News

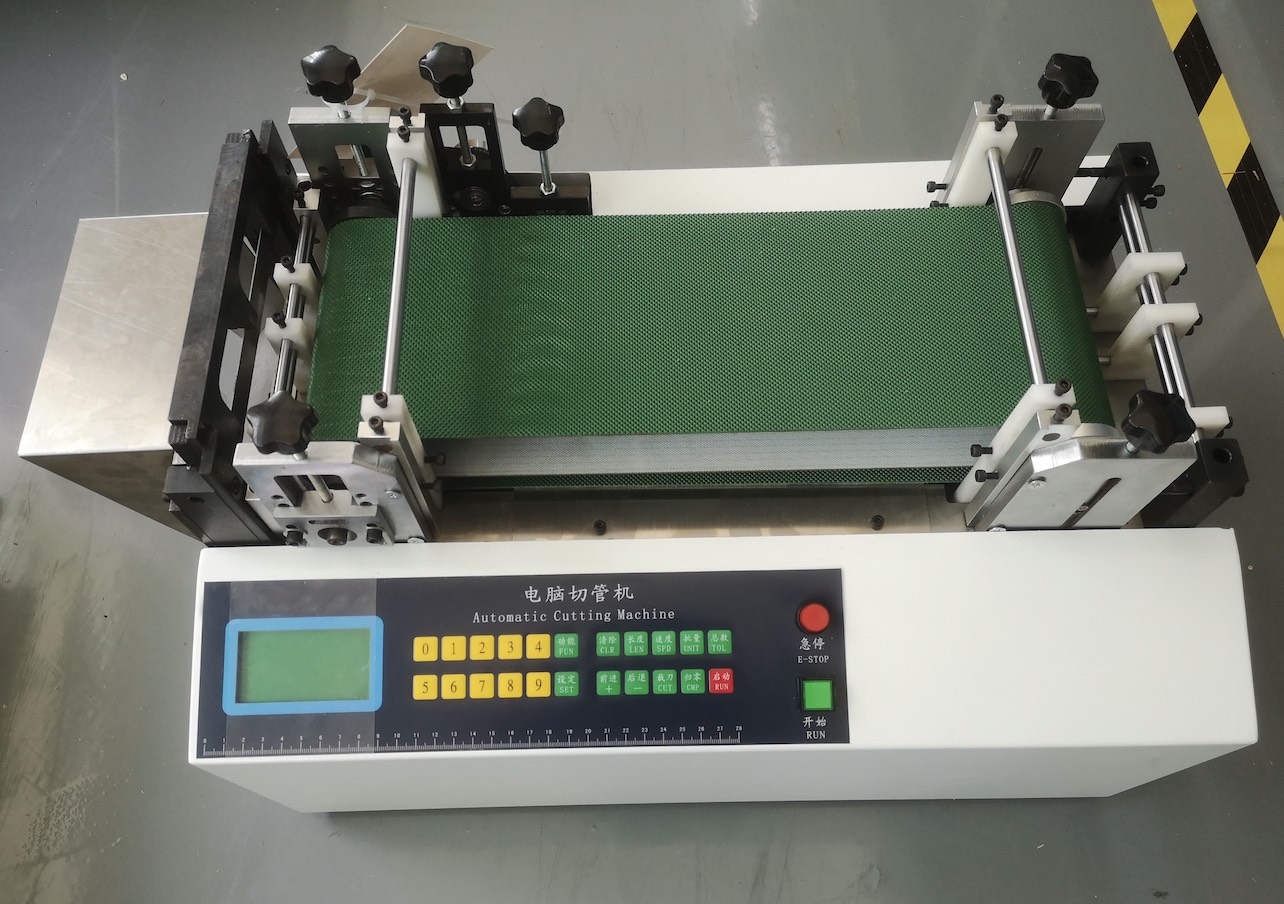

Small Automatic Hose Cutting Machine

Small automatic hose cutting machines have become indispensable tools in various industries, offering precise and efficient cutting solutions.

Importance of Hose Cutting Machines

Time Efficiency

Small automatic hose cutting machines significantly reduce cutting time compared to manual methods. With automated processes, operators can swiftly cut hoses to the desired lengths, thereby enhancing overall productivity and efficiency.

Cost Effectiveness

While initial investment may be higher, small automatic hose cutting machines offer long-term cost savings. By minimizing material waste and labor expenses, these machines contribute to improved profitability for businesses.

Types of Small Automatic Hose Cutting Machines

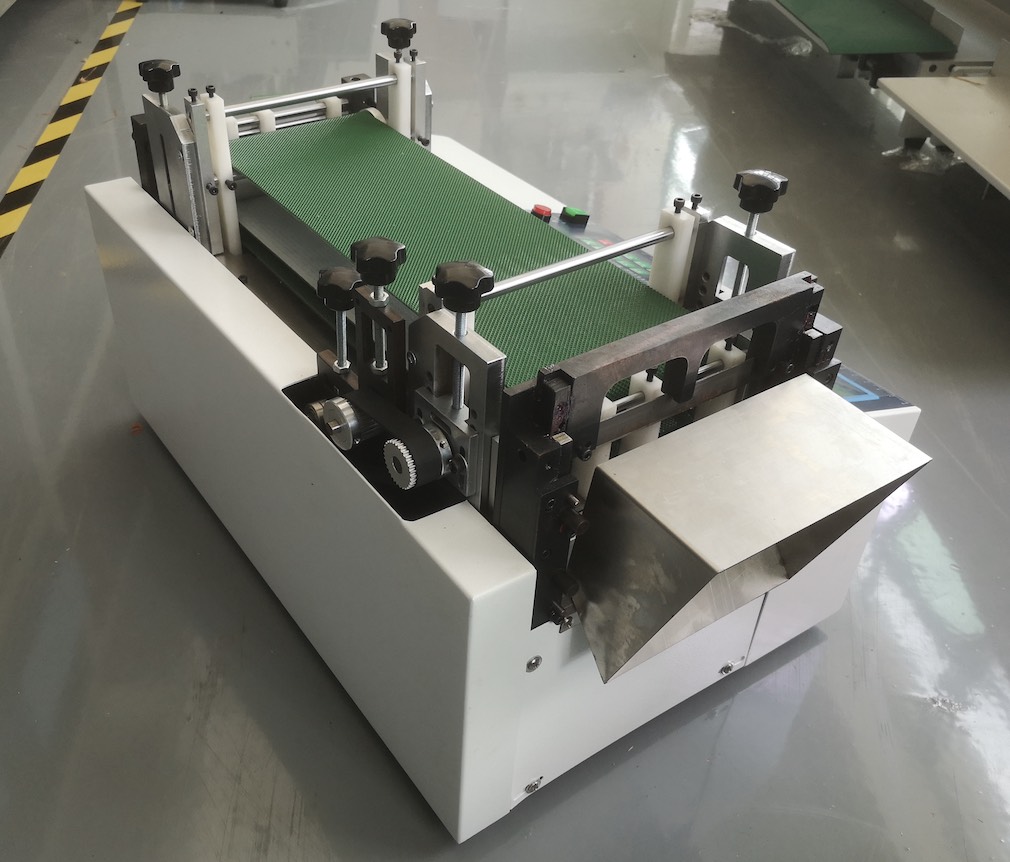

Benchtop Hose Cutting Machines

Benchtop hose cutting machines are stationary units designed for use in workshops or manufacturing facilities. They are ideal for high-volume cutting operations and offer enhanced stability and precision.

Portable Hose Cutting Machines

Portable hose cutting machines are compact and lightweight, making them suitable for on-site applications. These machines provide flexibility and convenience, allowing operators to cut hoses at various locations.

Features and Specifications

Cutting Capacity

Small automatic hose cutting machines come with varying cutting capacities to accommodate different hose sizes and materials. It's essential to choose a machine that meets the specific requirements of your application.

Cutting Speed

The cutting speed of these machines determines their efficiency in production processes. Higher cutting speeds enable faster throughput, reducing overall manufacturing time.

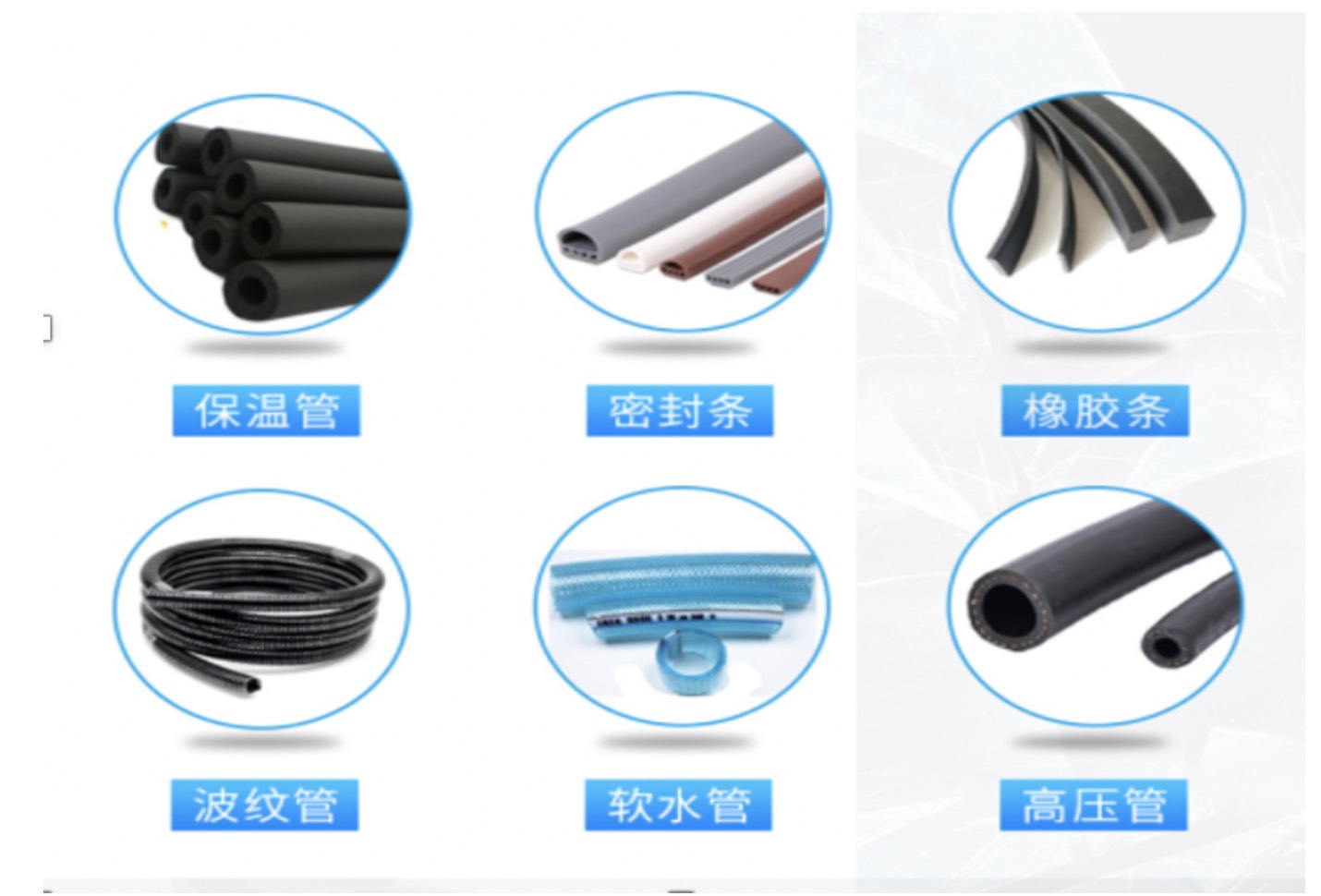

Material Compatibility

Small automatic hose cutting machines are capable of cutting a wide range of materials, including rubber, plastic, and metal hoses. Understanding the material compatibility of the machine is crucial for achieving optimal results.

Safety Features

Safety is paramount when operating machinery, and small automatic hose cutting machines are equipped with various safety features to prevent accidents. These may include emergency stop buttons, protective guards, and automatic shut-off systems.

Advantages of Using Small Automatic Hose Cutting Machines

Increased Productivity

By automating the cutting process, small automatic hose cutting machines significantly increase productivity, allowing businesses to meet tight production deadlines and customer demands.

Reduced Material Waste

Precision cutting minimizes material waste, leading to cost savings and environmental benefits. Small automatic hose cutting machines optimize material utilization, resulting in higher efficiency and sustainability.

Enhanced Safety

Automation reduces the risk of injuries associated with manual cutting methods. Small automatic hose cutting machines prioritize operator safety through built-in safety features and ergonomic design.

Applications in Various Industries

Automotive Industry

Small automatic hose cutting machines are widely used in the automotive industry for cutting hoses used in fuel systems, brake systems, and air conditioning systems. These machines ensure precise cuts, contributing to the reliability and performance of automotive components.

Manufacturing Industry

In the manufacturing industry, small automatic hose cutting machines play a crucial role in the production of various products, including machinery, appliances, and electronics. These machines streamline the manufacturing process, enabling efficient assembly and fabrication.

Construction Industry

Small automatic hose cutting machines are essential tools in the construction industry for cutting hoses used in hydraulic systems, pneumatic systems, and water distribution networks. Their precision cutting capabilities ensure the integrity and functionality of construction equipment and infrastructure.

Considerations When Choosing a Small Automatic Hose Cutting Machine

Budget

Before investing in a small automatic hose cutting machine, consider your budget and evaluate the cost-effectiveness of different options. While higher-priced machines may offer advanced features, ensure that they align with your budget constraints and long-term goals.

Cutting Requirements

Assess your cutting requirements in terms of hose size, material type, and production volume. Choose a machine that can accommodate your specific needs and provide the desired level of precision and efficiency.

Ease of Use

Look for a small automatic hose cutting machine that is user-friendly and easy to operate. Intuitive controls, clear instructions, and ergonomic design contribute to seamless integration into your production environment.

After-sales Support

Select a reputable manufacturer or supplier that offers comprehensive after-sales support, including technical assistance, maintenance services, and spare parts availability. Reliable support ensures the continued performance and longevity of your investment.

Maintenance Tips for Small Automatic Hose Cutting Machines

Regular Cleaning

Keep the machine clean and free of debris to prevent contamination and maintain optimal performance. Regular cleaning of cutting blades, guides, and other components prolongs the life of the machine and ensures consistent cutting results.

Lubrication

Apply lubricant to moving parts according to the manufacturer's recommendations to reduce friction and prevent wear. Proper lubrication extends the lifespan of critical components and prevents mechanical failures.

Calibration

Periodically calibrate the machine to ensure accurate cutting results. Calibration ensures that the machine operates within specified tolerances, maintaining consistency and precision in cutting operations.

Future Trends and Innovations

Integration with IoT

The integration of small automatic hose cutting machines with the Internet of Things (IoT) enables remote monitoring, predictive maintenance, and data-driven insights. IoT connectivity enhances operational efficiency and enables proactive management of cutting processes.

Enhanced Automation

Future advancements in automation technology will further improve the capabilities of small automatic hose cutting machines. Enhanced automation features, such as adaptive cutting algorithms and robotic integration, will optimize performance and flexibility.

Conclusion

Small automatic hose cutting machines are indispensable tools for precision cutting in various industries. With their advanced features, including precision cutting, time efficiency, and cost-effectiveness, these machines revolutionize production processes and contribute to improved productivity and profitability. By considering factors such as types, features, applications, and maintenance tips, businesses can harness the full potential of small automatic hose cutting machines to achieve their manufacturing goals.

FAQs

-

What are the key benefits of using small automatic hose cutting machines?

- Small automatic hose cutting machines offer precision cutting, time efficiency, and cost-effectiveness, leading to increased productivity and reduced material waste.

-

How do small automatic hose cutting machines contribute to safety in the workplace?

- These machines are equipped with safety features to prevent accidents and injuries, ensuring operator safety during cutting operations.

-

What factors should be considered when choosing a small automatic hose cutting machine?

- Factors such as budget, cutting requirements, ease of use, and after-sales support should be evaluated when selecting a small automatic hose cutting machine.

-

What maintenance practices are essential for prolonging the lifespan of small automatic hose cutting machines?

- Regular cleaning, lubrication, and calibration are key maintenance practices that ensure optimal performance and longevity of these machines.

-

What are the future trends and innovations in small automatic hose cutting machines?

- Future trends include integration with IoT for remote monitoring and predictive maintenance, as well as enhanced automation features for improved performance and flexibility.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Sunhose

Phone: +8618056044070

Tel: +8618056044070

Email: info@sino-hose.com

Add: New & Hi-Tech.Industrial Development Zone,Anhui,China