Industry New

Introduction of rubber

According to the appearance of rubber: the rubber can be divided into four categories: solid rubber (also known as dry rubber), emulsion rubber (referred to as latex), liquid rubber, and powder rubber.According to the physical form of rubber: the rubber can be divided into hard rubber and soft rubber, raw rubber, and mixed rubber.

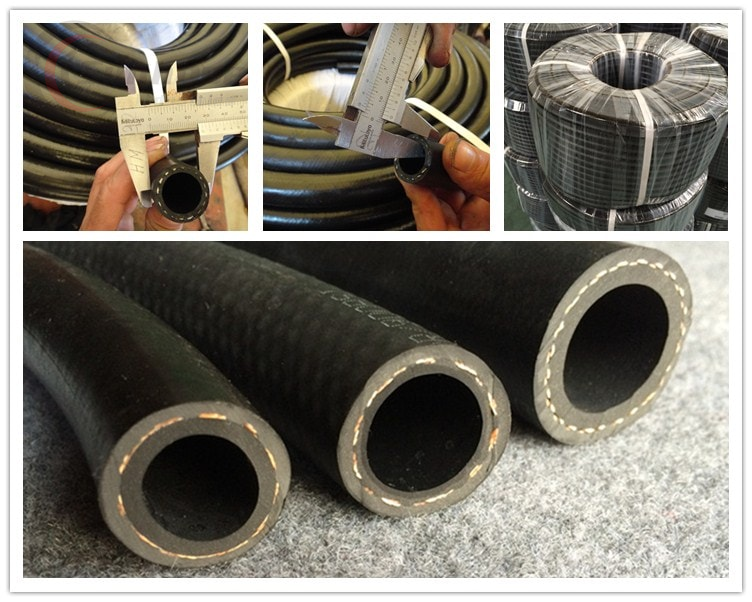

Rubber products are widely used in all aspects of industry or life. In the rubber products, we should be the most common to see is the rubber hose, made of rubber material than ordinary hose more strong and ductile, and oil resistance, wear resistance, more anti-aging.

In order to improve the performance of rubber products, a series of processing processes must be carried out on the raw rubber in production.

Under certain conditions, the raw rubber in the rubber compound and the vulcanizing agent are chemically reacted, so that it is cross-linked by linear macromolecules. The macromolecules with three-dimensional network structure make the rubber compound have high strength, high elasticity, high wear resistance, corrosion resistance and other excellent properties. This process is called rubber vulcanization.The rubber before vulcanization is raw rubber. Although raw rubber has advantages, its disadvantages are low strength and small elasticity; cold makes it hard, heat makes it sticky, and it is easy to age. Vulcanized rubber refers to vulcanized rubber, which has the characteristics of not sticking and not easy to break. Most rubber products are made of this kind of rubber. Also called cooked rubber, commonly known as rubber or rubber. The general term for rubber after vulcanization. After vulcanization, a three-dimensional structure is formed in the raw rubber, which has high elasticity, heat resistance, tensile strength, and insolubility in organic solvents. The vast majority of rubber products are vulcanized rubber. Reasonable determination and strict control of vulcanization process conditions are the keys to determining the quality of rubber products.

The compression set is one of the important performance indicators of rubber products. The size of the vulcanized rubber compression set is related to the elasticity and recovery of vulcanized rubber. The size of permanent deformation is mainly dominated by the change of rubber recovery ability.

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Sunhose

Phone: +8618056044070

Tel: +8618056044070

Email: info@sino-hose.com

Add: New & Hi-Tech.Industrial Development Zone,Anhui,China